Sewing machines: Difference between revisions

| Line 15: | Line 15: | ||

==Sewing Machine Principles== | ==Sewing Machine Principles== | ||

Regular users of a sewing machine will be familiar with its operation and can skip this section, which is provided for occasional users or those simply faced with a non-working machine. | Regular users of a sewing machine will be familiar with its operation and can skip this section, which is provided for occasional users or those simply faced with a non-working machine. | ||

===Sewing Machine Controls=== | |||

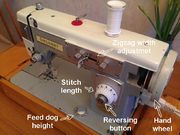

The accompanying pictures show a sewing machine probably dating from the 1950's. This has the advantage for demonstration purposes of having all the basic controls easily seen. | |||

[[File:Img_0444a.jpg|180px|thumb|left|Sewing machine controls 1/3.]] | |||

[[File:Img_0445a.jpg|180px|thumb|right|Sewing machine controls 2/3.]] | |||

At the business end of the sewing machine, the foot presses down on the work, enabling the feed dogs below to feed i through the machine by a kibd of walking motion. Alternative feet may be provided for different jobs and they are secured to a vertical shaft with a knurled knob. | |||

An adjustment on the top allows the pressure of the foot on the work to be adjusted. | |||

The top thread passes through an adjustable tensioner, allowing the tension of the top thread to be equalised with that of the bottom thread. When properly adjusted, the threads should engage with one another within the fabric. Badly adjusted, the top thread will lie on top of the fabric or the bottom thread on the bottom, with the other thread passing through the fabric and back again. | |||

Behind the head of the machine a lever allows the foot to be raised in order to insert or withdraw the work, and lowered in order to sew. This is normally operated blind by feel. | |||

[[File:Img_0443a.jpg|180px|thumb|left|Sewing machine controls 3/3.]] | |||

The hand wheel on the right is driven by a belt from the motor. You can turn it by hand to stitch one stitch at a time, or to ensure the needle is disengaged before inserting or removing the work. | |||

A bobbin winder (missing on this particular machine) engages with the hand wheel in order to load bobbins with thread. A knurled knob on the hand wheel allows it to be disengaged from the sewing machine mechanism whilst winding bobbins. | |||

The stitch length adjuster varies the distance the work is moved between stitches. The reversing button (or lever) allows you to sew in the reverse direction. (You should always do a couple of reverse stitches at the start and end of a line of stitches to lock the ends.) | |||

The feed dog height adjustment allows the feed dogs to optimally grip fabrics of different types. | |||

==Common problems and solutions== | ==Common problems and solutions== | ||

Revision as of 17:41, 28 January 2016

This page covers the maintenance of domestic sewing machines.

Summary

Older sewing machines are virtually indestructible and with simple maintenance can continue to give good service almost indefinitely. Newer machines often have plastic parts which wear out quite quickly. Nevertheless, all machines can give longer service, properly cared for.

Safety

- Always unplug from the mains before staring any maintenance or repair work, in order to eliminate the risk of electric shock or physical injury from moving parts.

- Sewing machine oil is highly flammable and can be ignited by overheating parts.

- Older machines, particularly can weigh as much as 20kg. Take care when lifting or when tipping over to service the under side.

Warning

On no account use anything but sewing machine oil to lubricate the mechanism. Do not use WD40, or 3-in-1, or bicycle oil, or engine oil, or grease, or olive oil, or vaseline, or snake oil, or peanut butter. None of these are sewing machine friendly.

Sewing Machine Principles

Regular users of a sewing machine will be familiar with its operation and can skip this section, which is provided for occasional users or those simply faced with a non-working machine.

Sewing Machine Controls

The accompanying pictures show a sewing machine probably dating from the 1950's. This has the advantage for demonstration purposes of having all the basic controls easily seen.

At the business end of the sewing machine, the foot presses down on the work, enabling the feed dogs below to feed i through the machine by a kibd of walking motion. Alternative feet may be provided for different jobs and they are secured to a vertical shaft with a knurled knob.

An adjustment on the top allows the pressure of the foot on the work to be adjusted.

The top thread passes through an adjustable tensioner, allowing the tension of the top thread to be equalised with that of the bottom thread. When properly adjusted, the threads should engage with one another within the fabric. Badly adjusted, the top thread will lie on top of the fabric or the bottom thread on the bottom, with the other thread passing through the fabric and back again.

Behind the head of the machine a lever allows the foot to be raised in order to insert or withdraw the work, and lowered in order to sew. This is normally operated blind by feel.

The hand wheel on the right is driven by a belt from the motor. You can turn it by hand to stitch one stitch at a time, or to ensure the needle is disengaged before inserting or removing the work.

A bobbin winder (missing on this particular machine) engages with the hand wheel in order to load bobbins with thread. A knurled knob on the hand wheel allows it to be disengaged from the sewing machine mechanism whilst winding bobbins.

The stitch length adjuster varies the distance the work is moved between stitches. The reversing button (or lever) allows you to sew in the reverse direction. (You should always do a couple of reverse stitches at the start and end of a line of stitches to lock the ends.)

The feed dog height adjustment allows the feed dogs to optimally grip fabrics of different types.

Common problems and solutions

Machine seized up

After many years of disuse a machine may completely seize up. Lubricate thoroughly as described under Maintenance. You may have to leave the oil for a while in order to ease the parts and repeat several times, wiping away any excess.

Snagging or breaking thread

First of all, if you have disassembled anything, make sure you have reassembled it correctly and that you can turn the hand wheel freely. Ensure the needle isn't bent and that it feels smooth as you run it between your fingers from the shank to the tip.

Make sure the machine is threaded correctly. If you don't have a printed instruction booklet, look on the Internet for instructions for the same or a similar model. On some machines you thread the needle from left to right, and from right to left on others. It's important to get it right.

Ensure the bobbin is threaded and fitted correctly. The bobbin carrier has a sharp point which catches the top thread. Problems can result if this has been roughened by needle strikes. Smooth it with fine emery as described under Maintenance.

Before starting to sew, make sure there isn't excessive slack in the top thread. If you have just fitted the bobbin, place your finger on the loose end of the top thread and turn the hand wheel as if to make one stitch. When you now pull the top thread it should draw up the bottom thread. Place your finger on the loose ends of both threads as you make the first stitch or two otherwise they may snag.

Poor speed control

If nothing happens when you press the foot pedal a little, but the machine races when you press it just a little more then it will be very hard to sew successfully. The foot pedal may simply need lubricating. On older machines this will contain a rheostat, which is a variable resistance wired in series with the motor. Newer machines will more likely have an electronic speed control similar to a dimmer switch.

First, double check that it's not still plugged in. You will need to examine it to determine how to disassemble it. Do not use sewing machine oil, but rather any light lubricating oil, or grease on sliding parts, and keep oil and grease away from all electrical contacts.

Also, check the belt tension. Check out the page on Electric motors if the motor may be faulty. Replacing the brushes or cleaning the commutator might be necessary. The motor bearings can be lubricated with light lubricating oil.